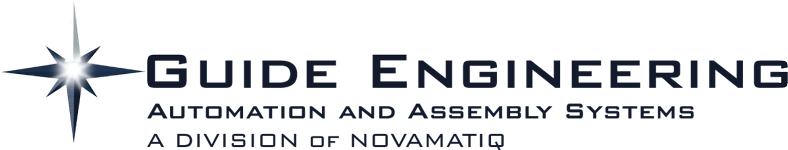

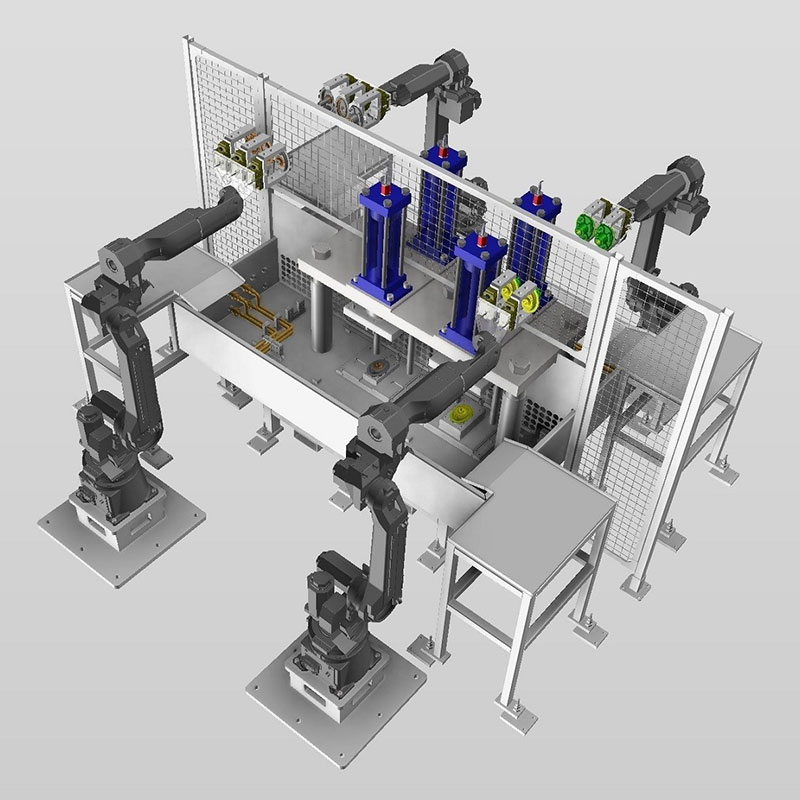

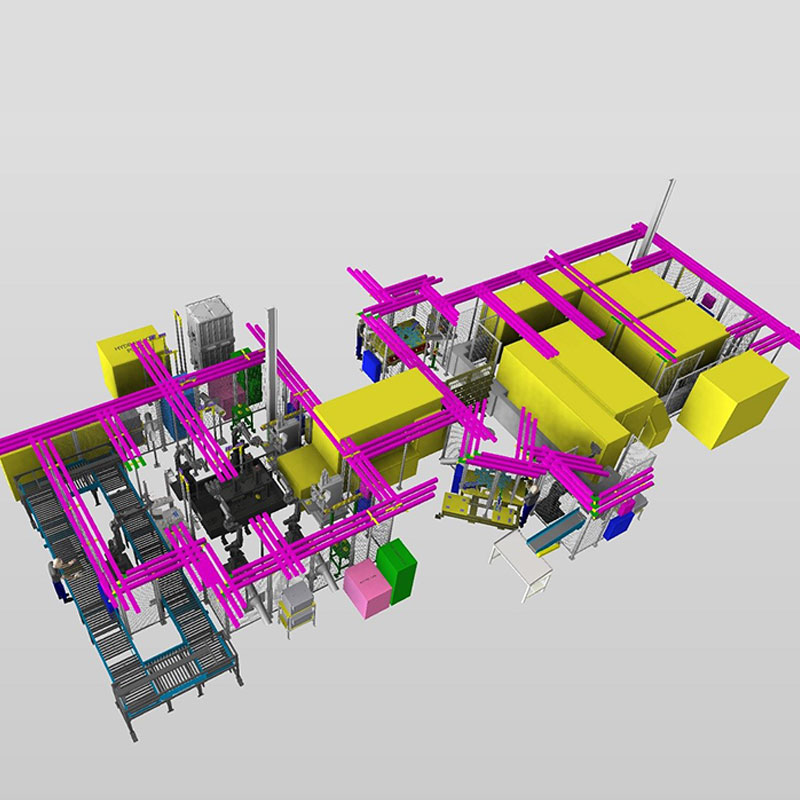

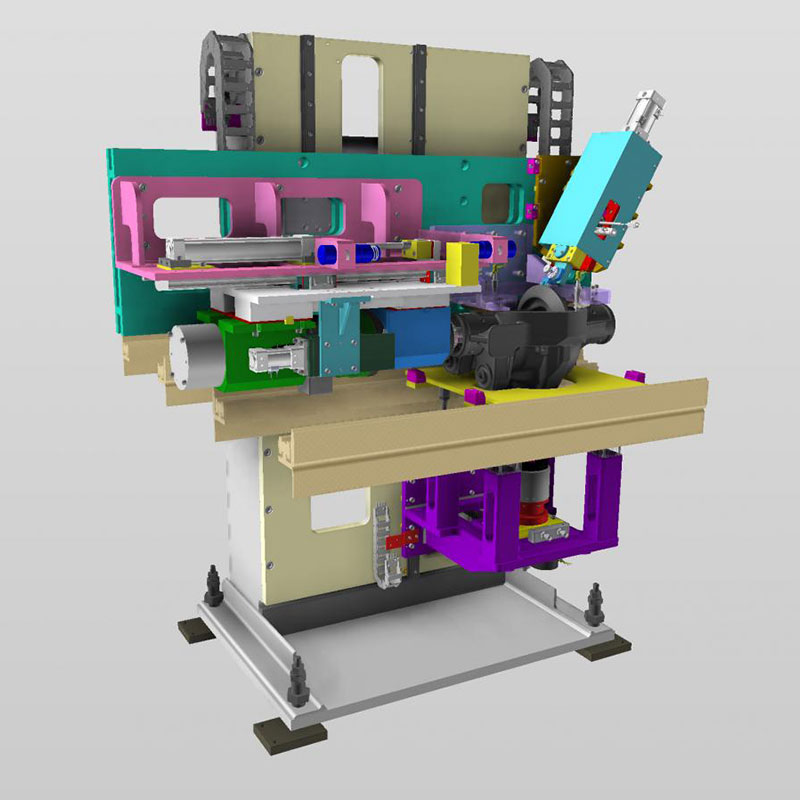

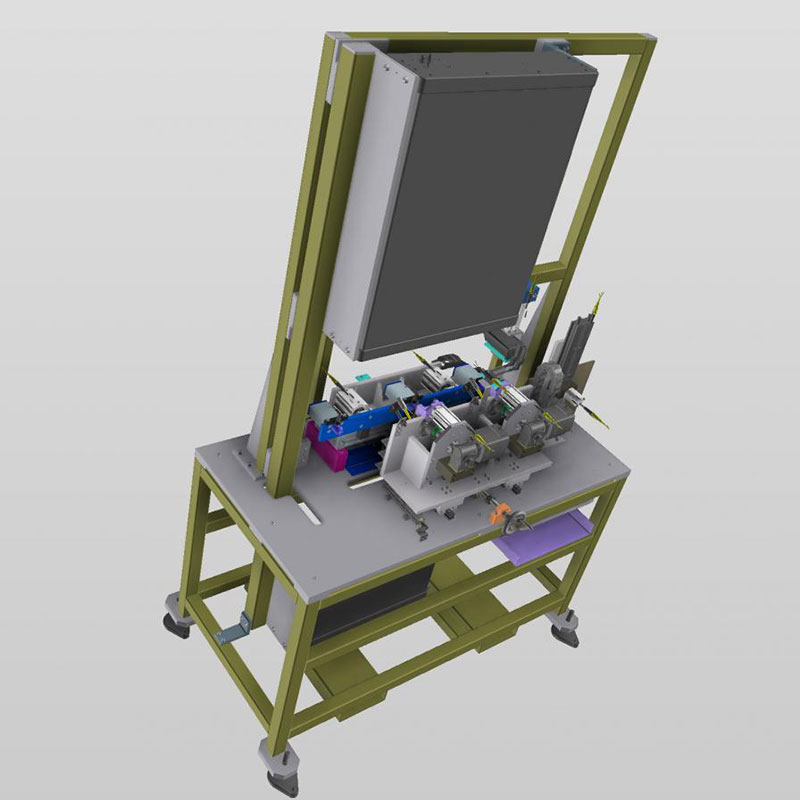

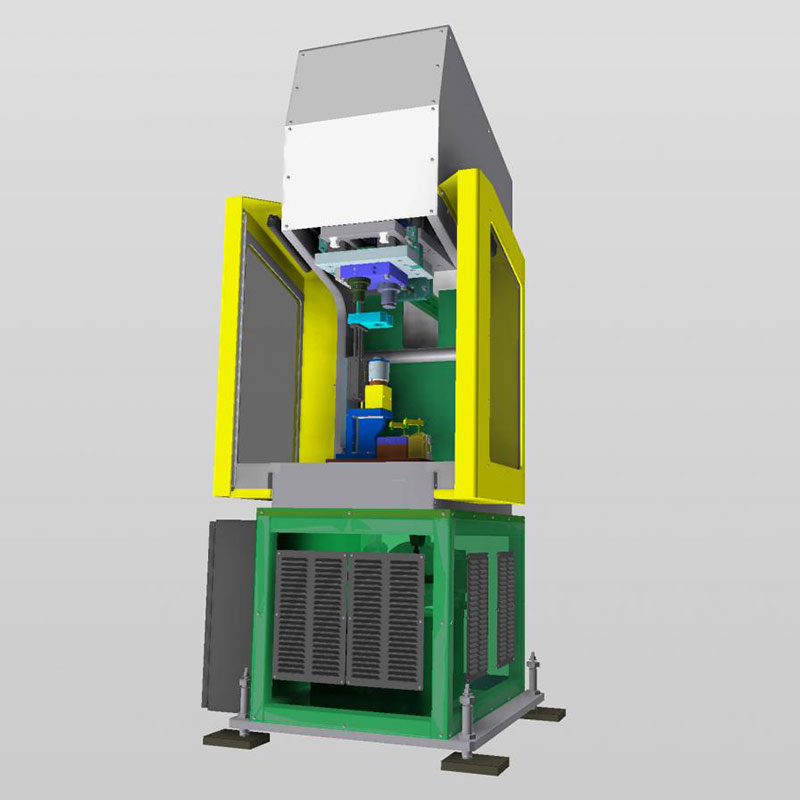

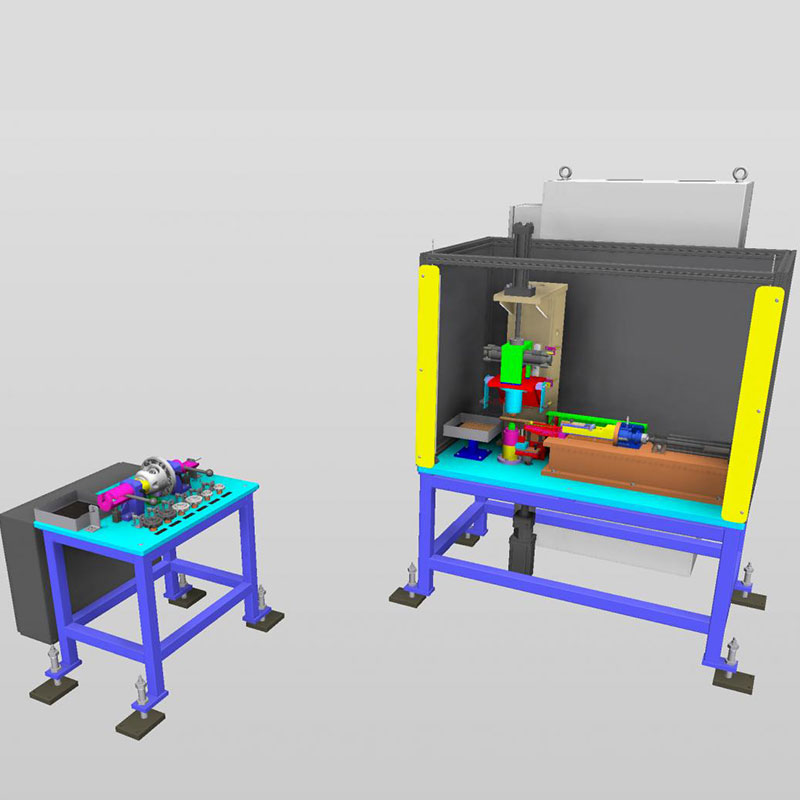

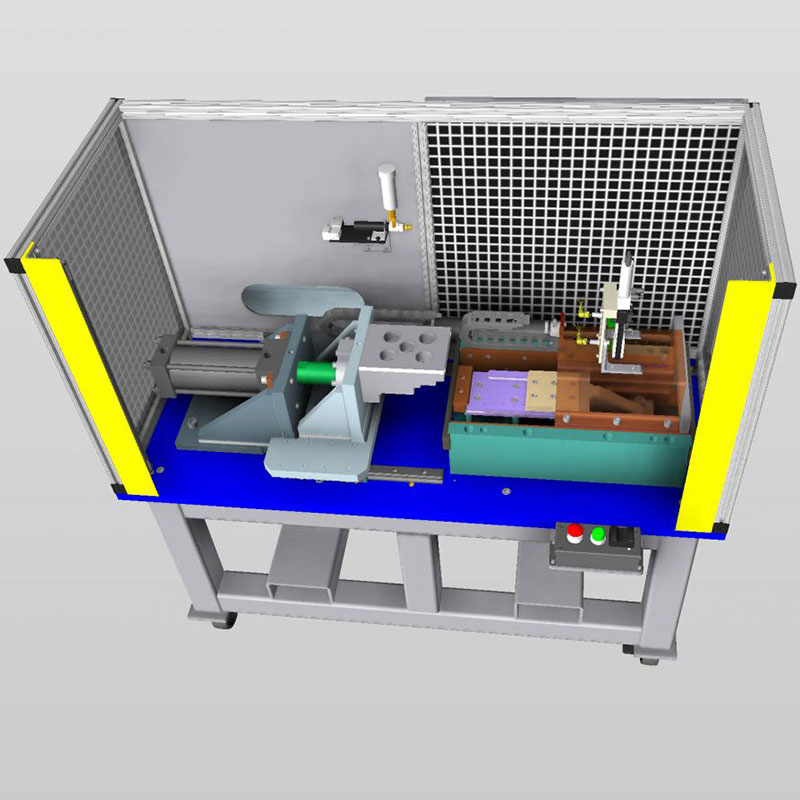

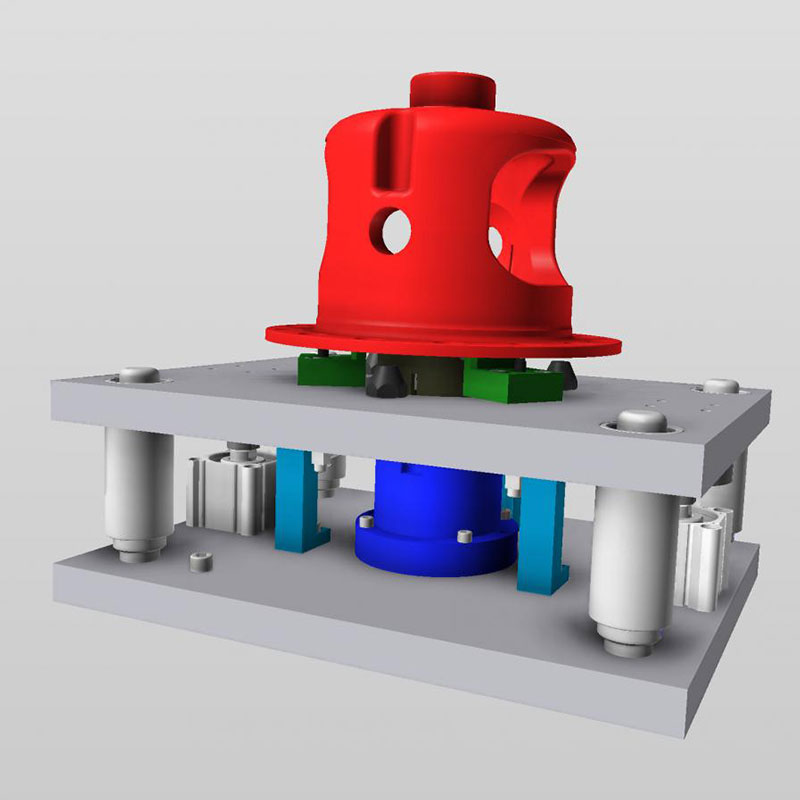

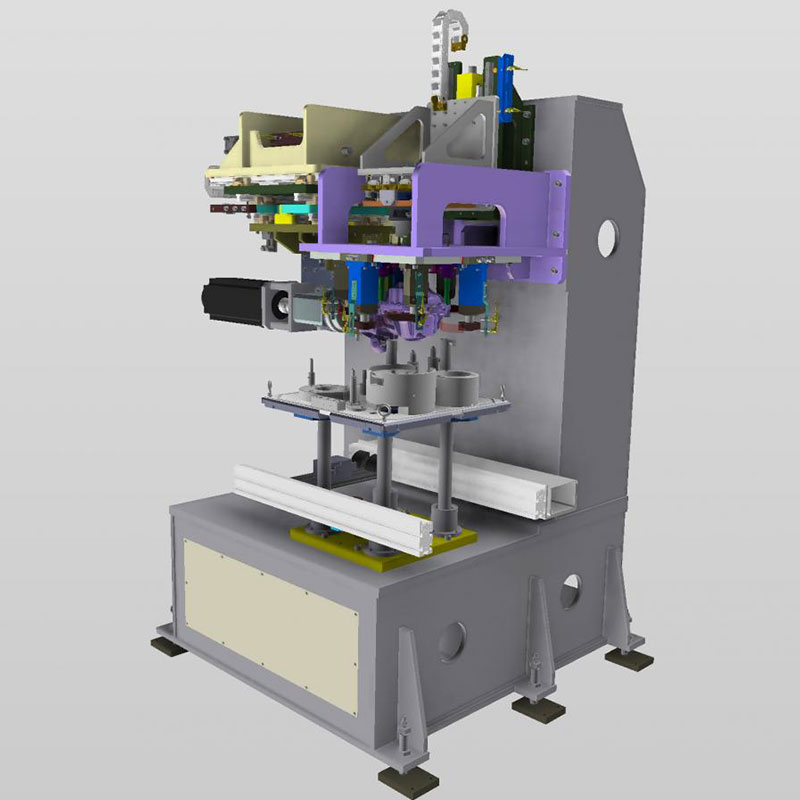

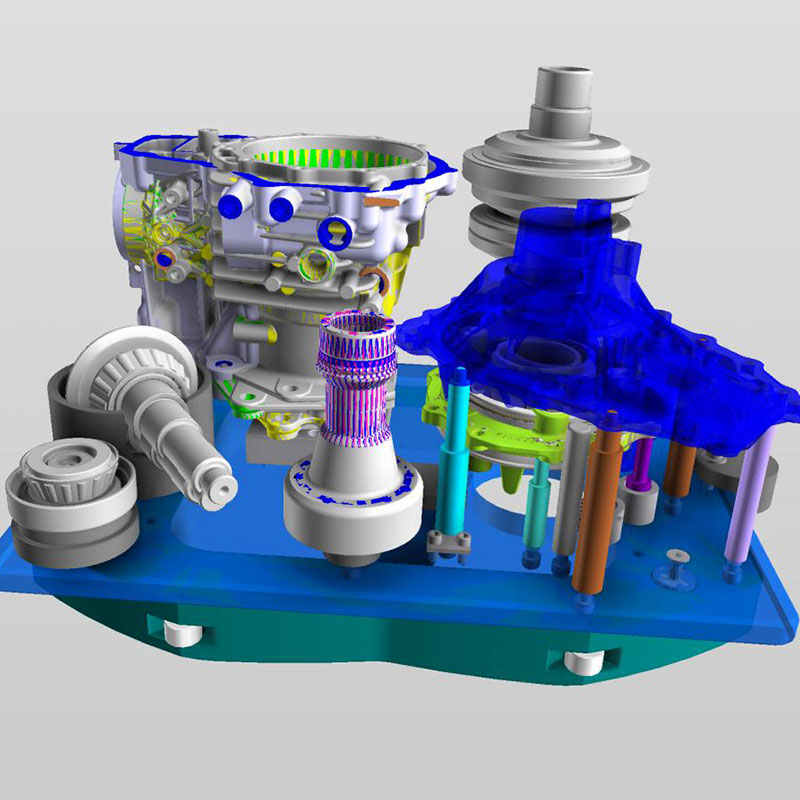

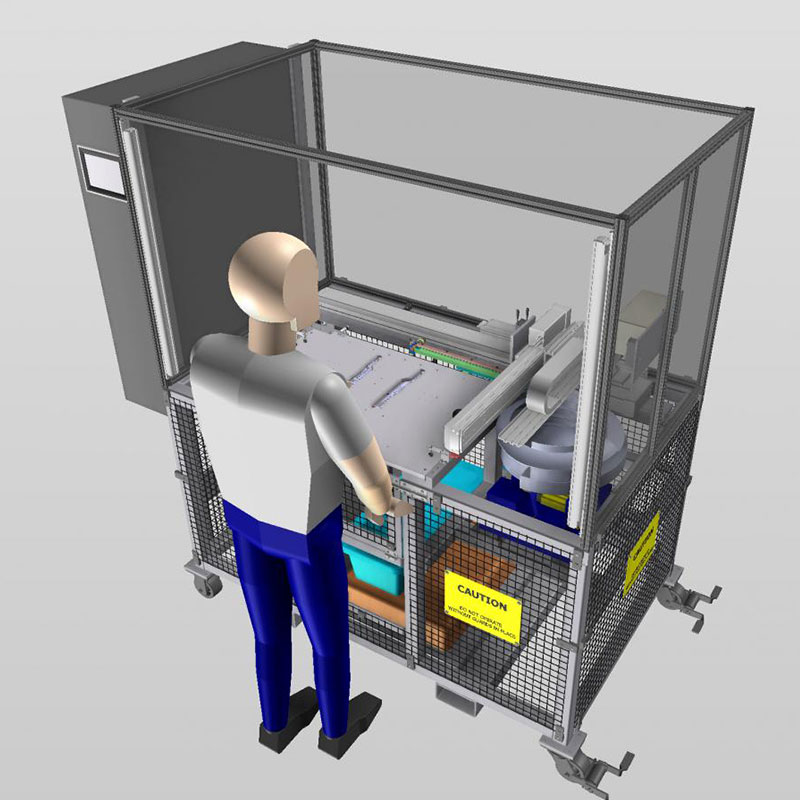

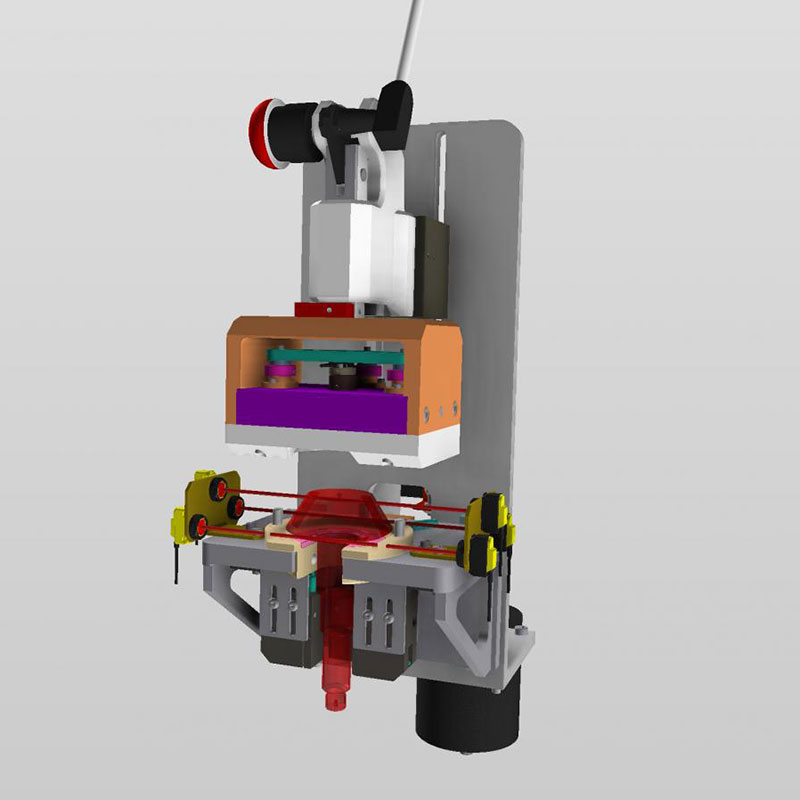

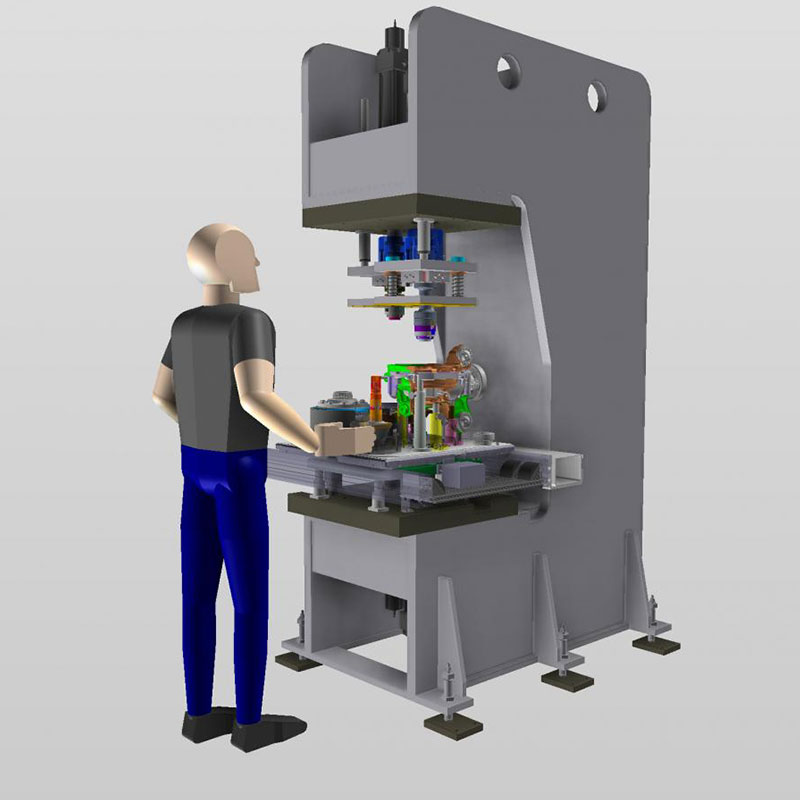

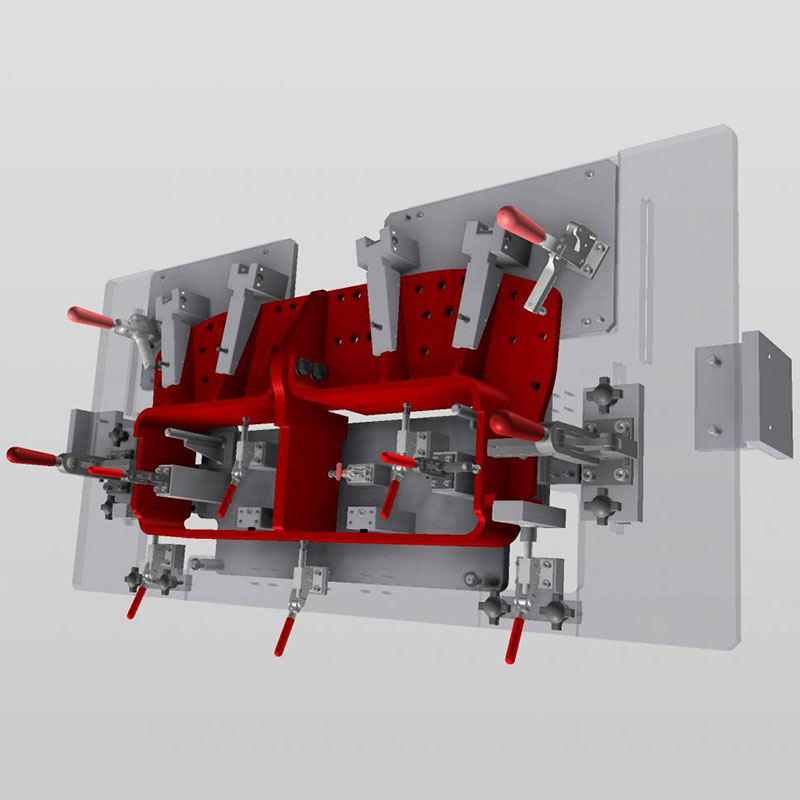

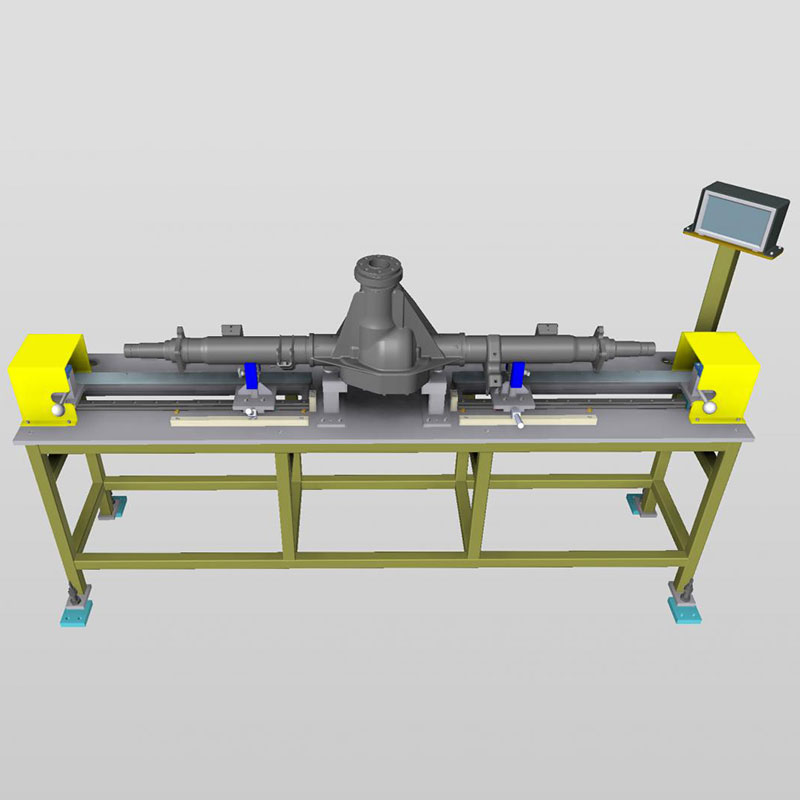

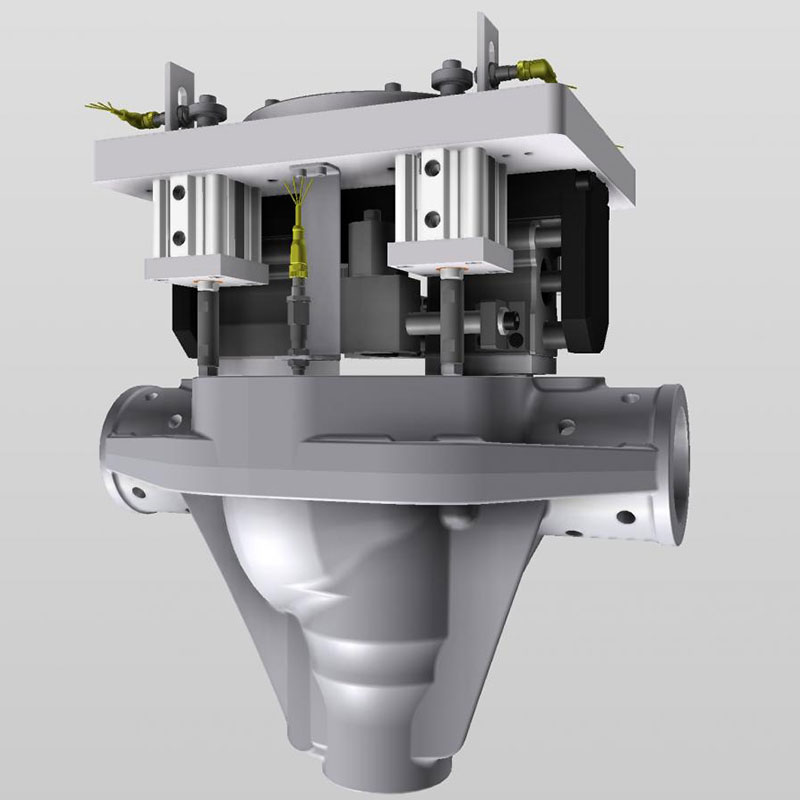

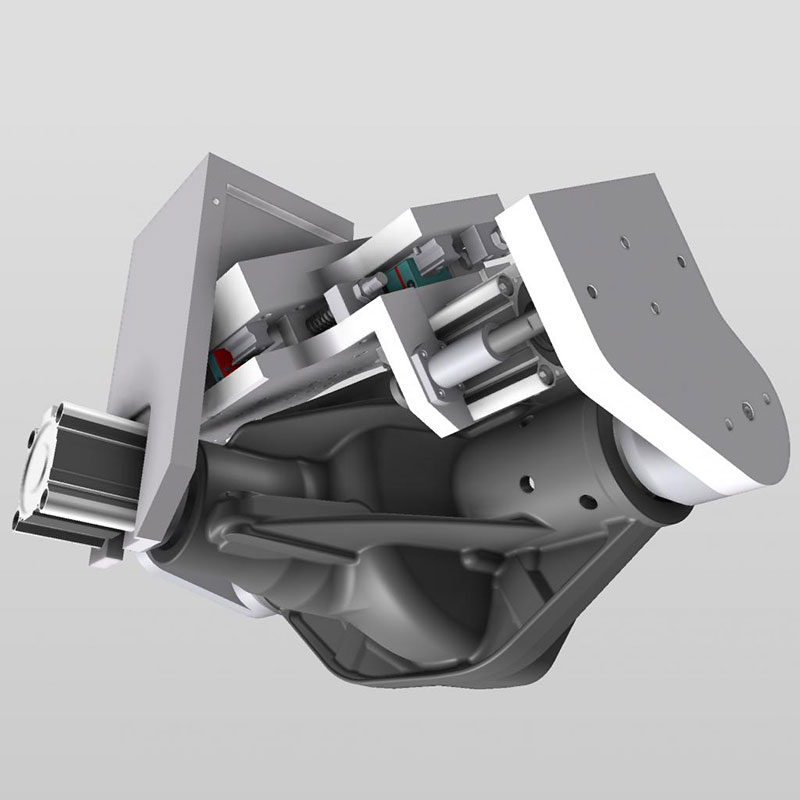

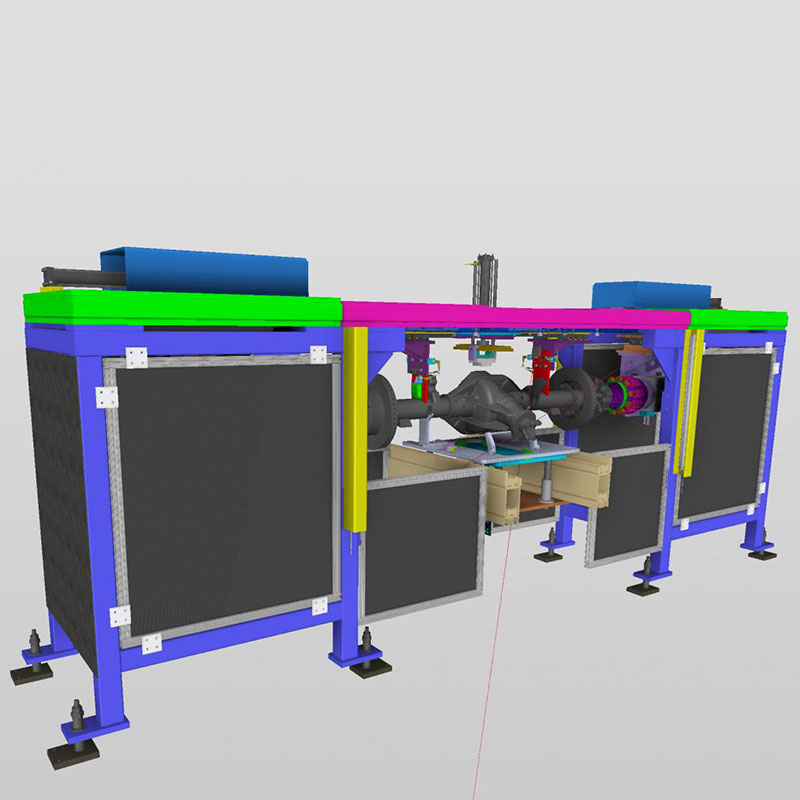

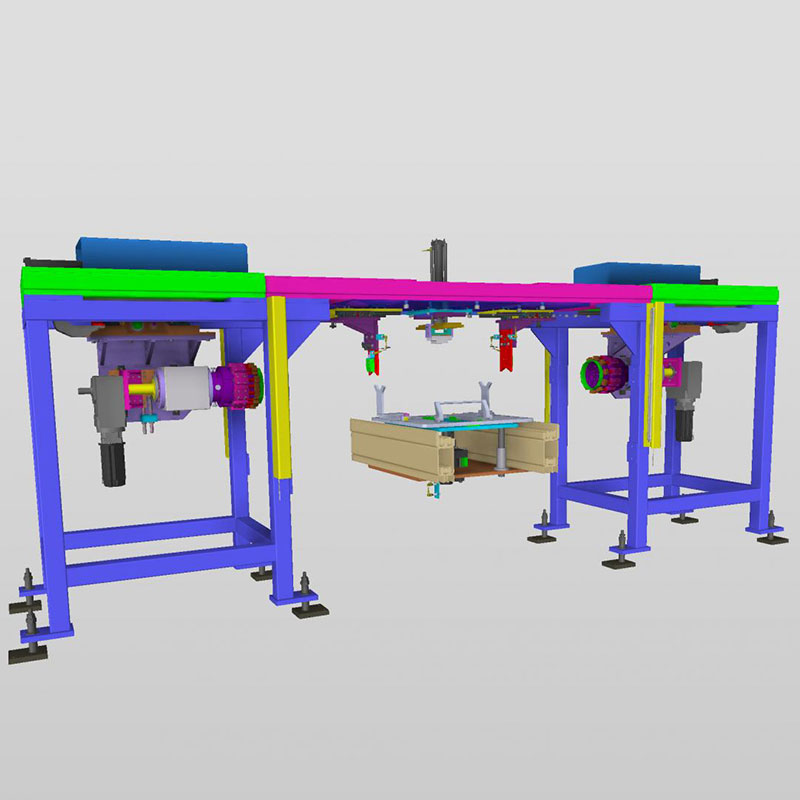

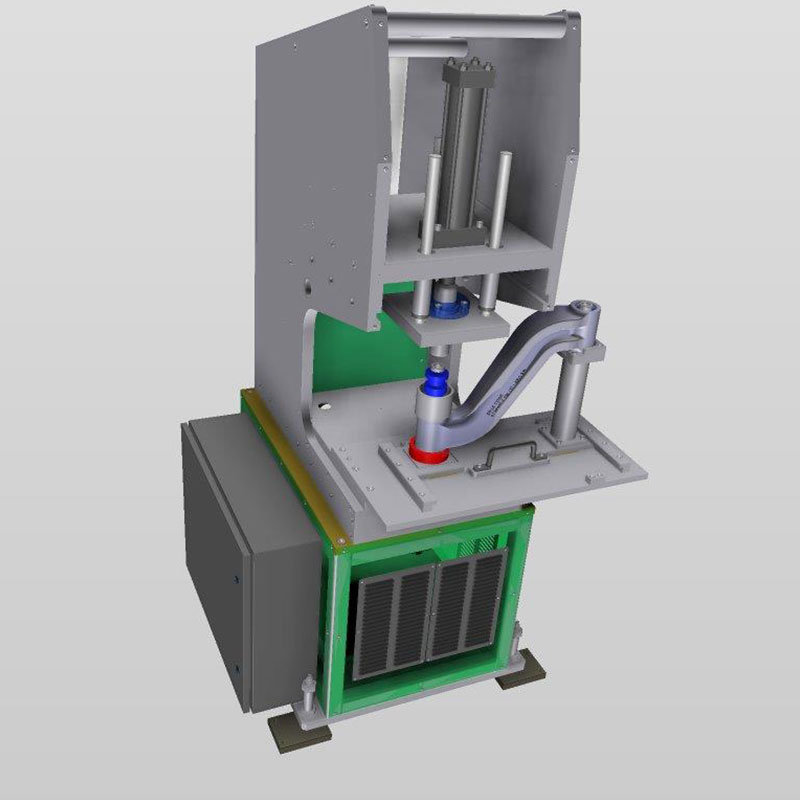

Mechanical Engineering

Guide Engineering’s mechanical design staff utilizes the latest modeling software. We provide conceptual designs, FEA studies, and work cell simulations. Every design takes into account safety, simplicity, and ergonomics.

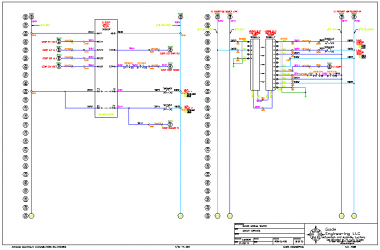

ELECTRICAL AND SOFTWARE ENGINEERING

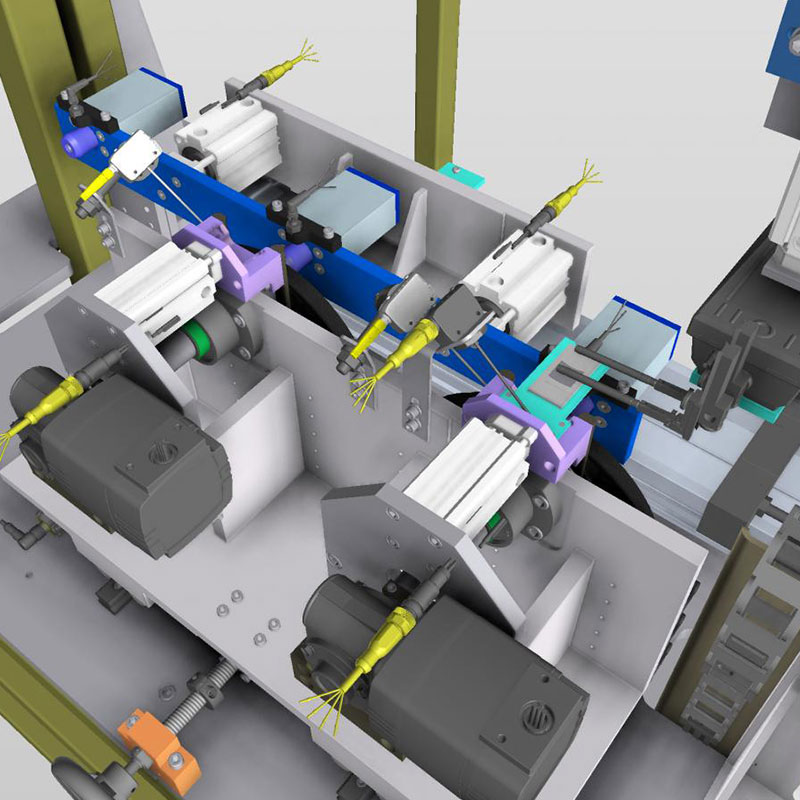

Our electrical engineering staff has the ability to design and process any type of project; from a stand-alone machine, to an integrated assembly line. Our designers utilize AutoCAD electrical design software, making us a highly efficient group to partner with.

Our software engineers’ expertise includes PLC programming, HMI and PC development. We are also accustomed to a variety of industrial devices, motion control systems, and networking.

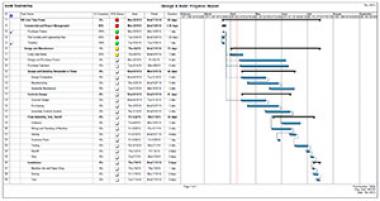

PROJECT MANAGEMENT

Our project management and engineering group plays an integral part in the development and completion of all projects. This group is involved in all phases of the project, from estimating, to the completion of the project.

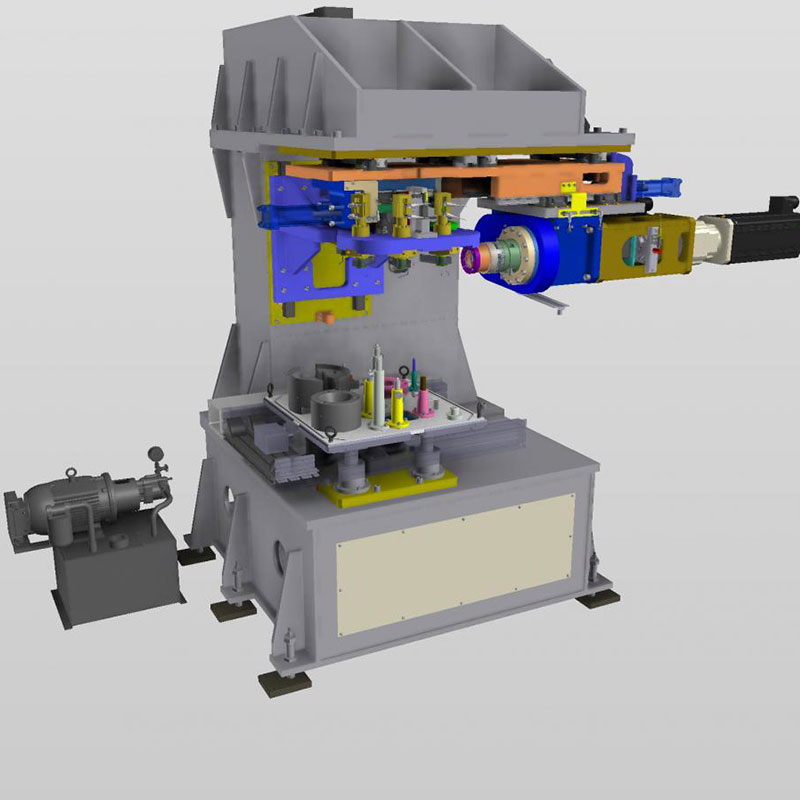

MACHINING

Our In-house machining capability allows for quality and on time delivery of your project and critical components.

We are a full service machining facility employing certified class A Tool and Die makers. We are a certified employer and sponsor of the Tool and Die Apprenticeship program governed by the Bureau of Apprenticeship Training.

- CNC Lathes and Machining Centers Utilizing CAD/CAM Software

- Manual Lathes and Milling Machines

- Horizontal and Vertical Jig Boring

- Jig Grinding

- Surface Grinding

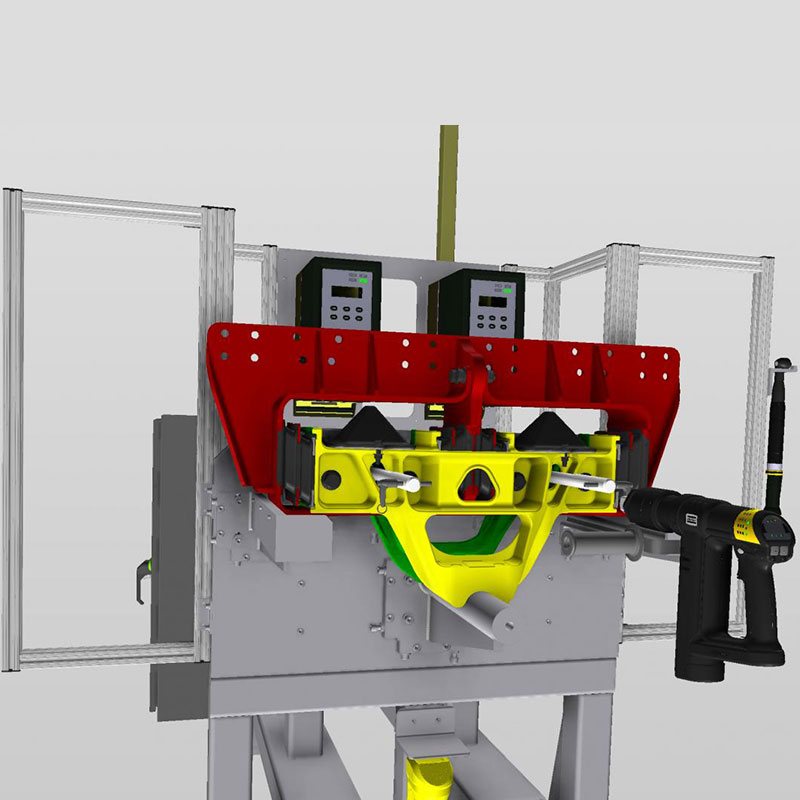

PANEL BUILD

Guide Engineering employs industrial electricians who are experienced in building electrical control systems and in machine integration. All of our equipment is designed and built to comply with applicable standards.