ASSEMBLY SYSTEMS

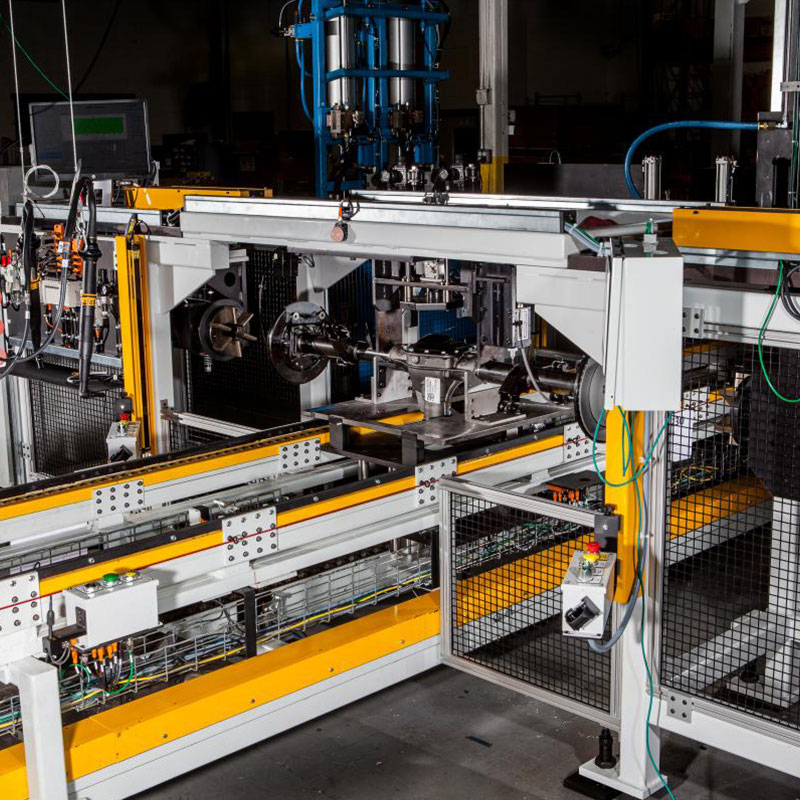

We design and build assembly solutions for a variety of industries. Our projects include single assembly machines, multi-process assembly cells, and in-line palletized assembly lines.

We will provide you with an assembly process that meets your production requirements.

- Pressing

- Bolt and Nut Tightening

- Staking and Forming

- Welding

- Dynamic Torque Applications

- Dispensing

- Guided Manual Assembly

- Automated Assembly

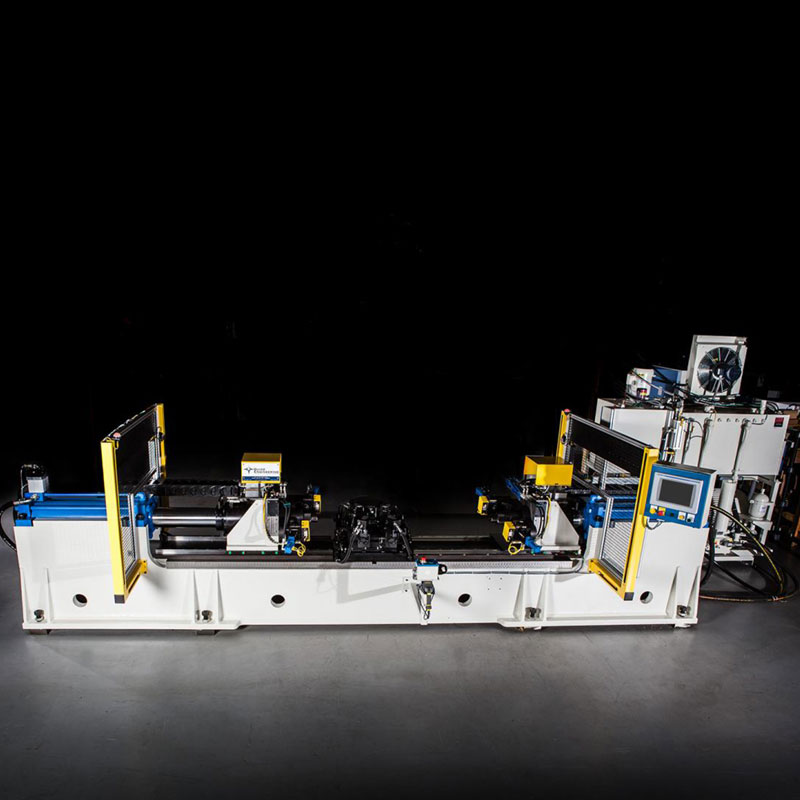

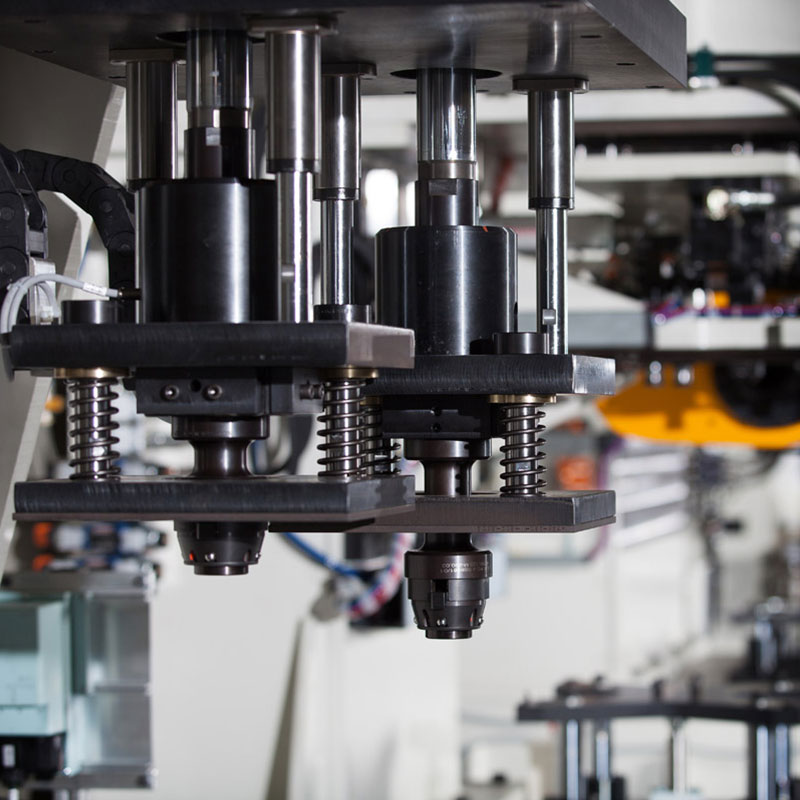

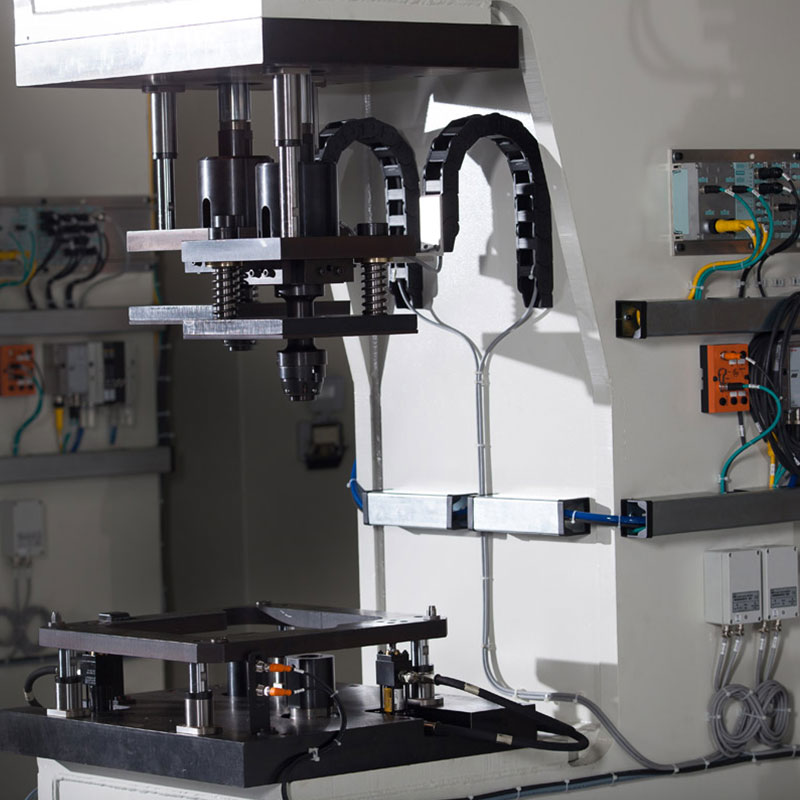

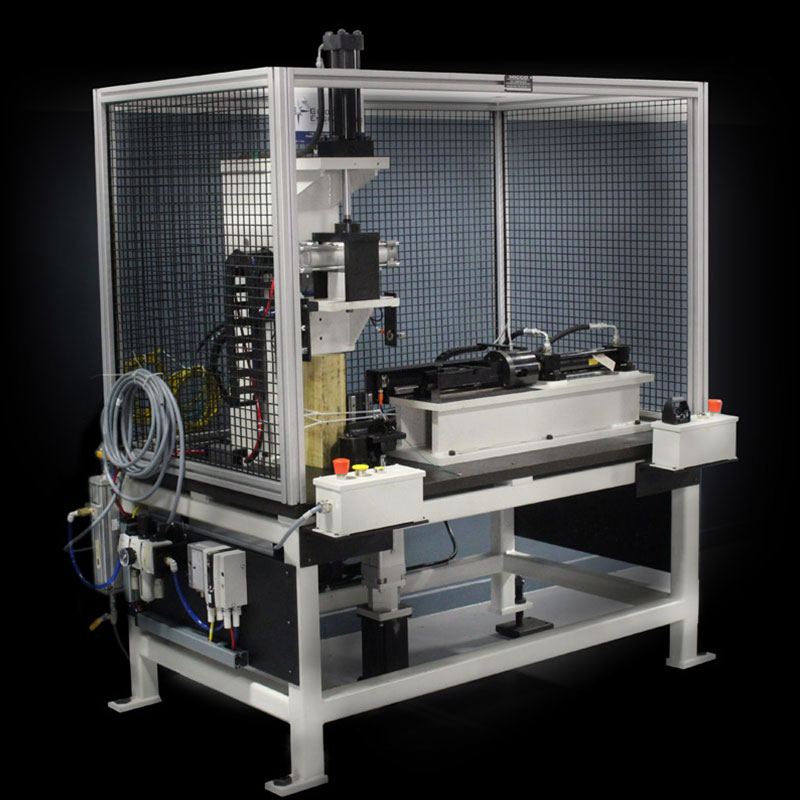

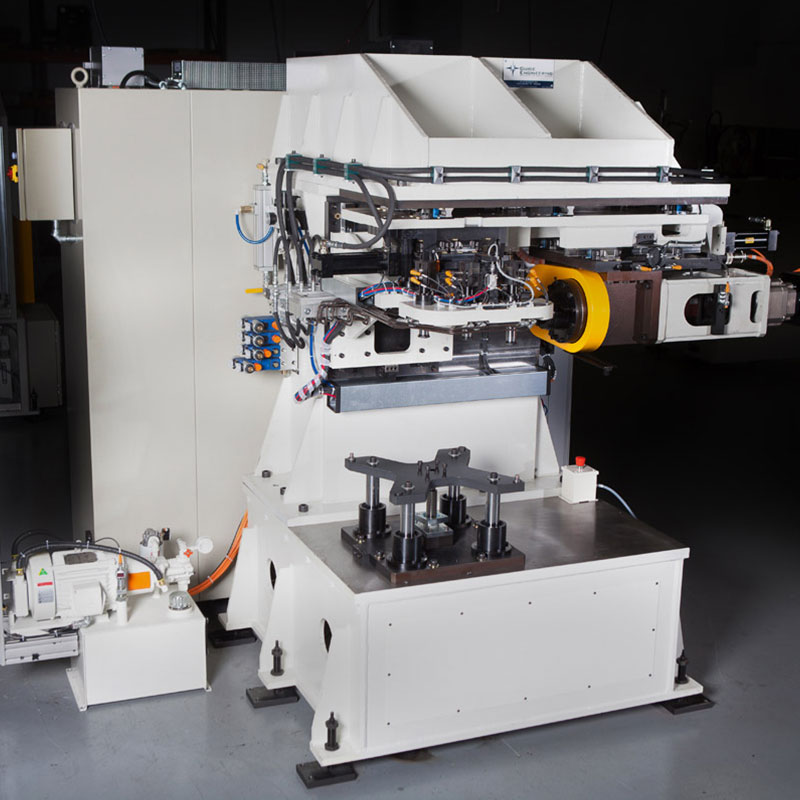

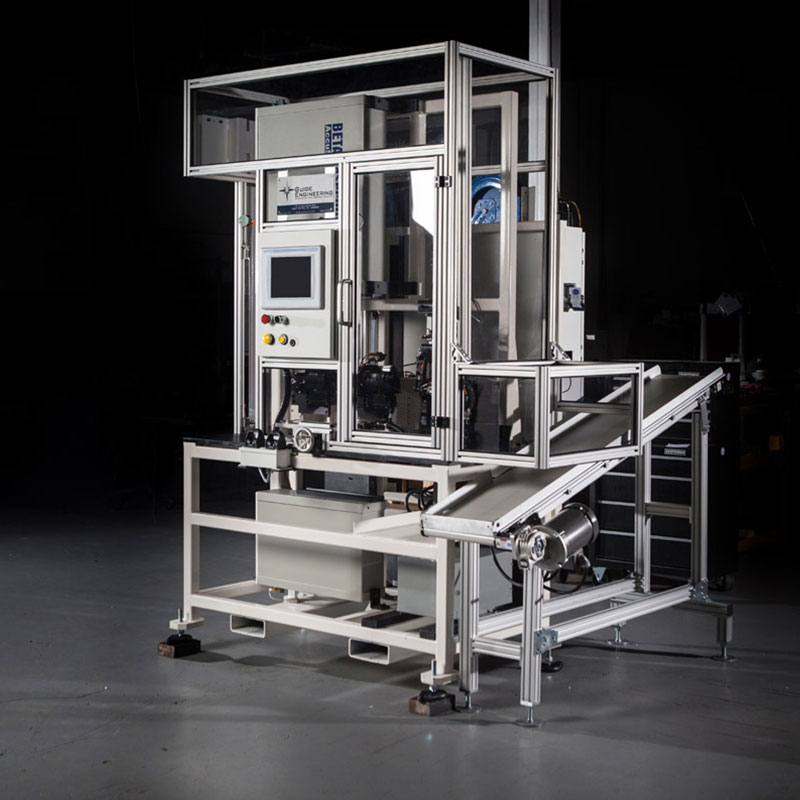

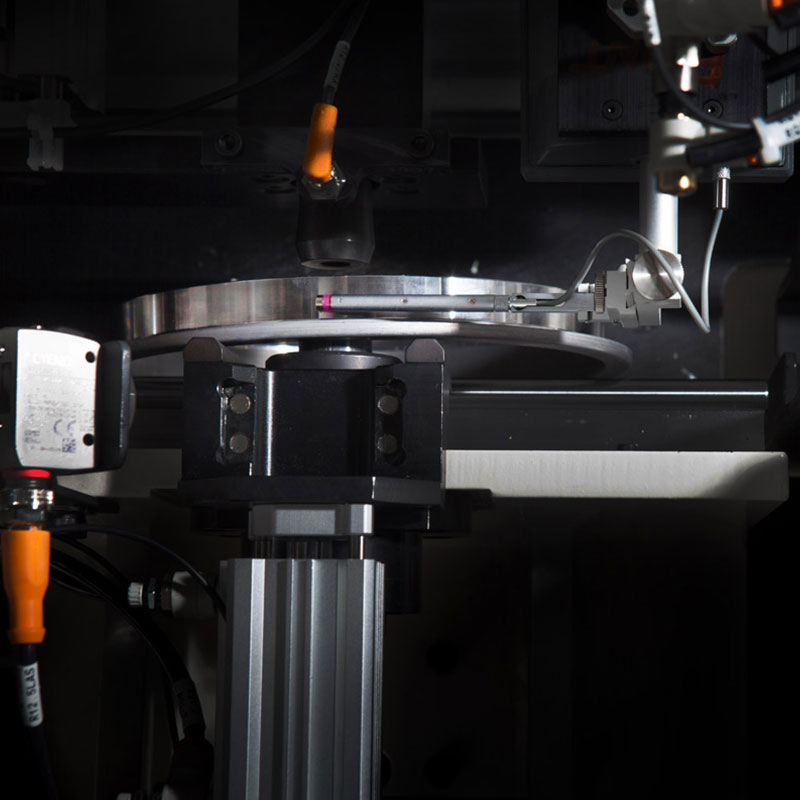

PRESSING

Guide Engineering designs and builds our own presses ranging from 1 ton to 100 tons.

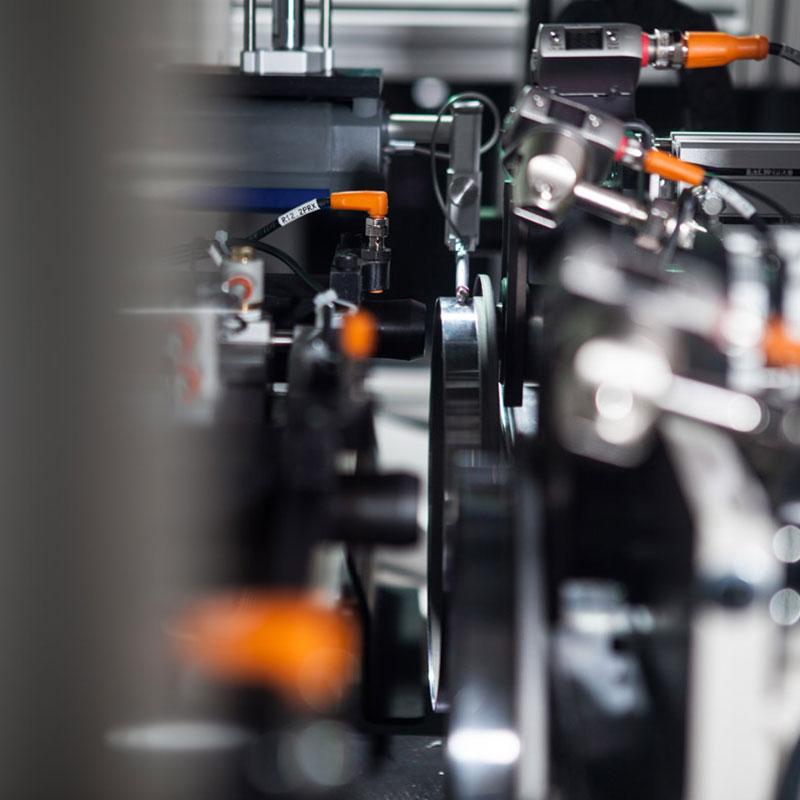

- Applications

- – Bearings and Seals

- – Tubes

- – Shafts

- – Suspension Components

- – Bushings

- Press types

- – Bench Mount and Floor Mount

- – Vertical and Horizontal

- – C-Frame

- – Two Post and Four Post

- – Special Applications

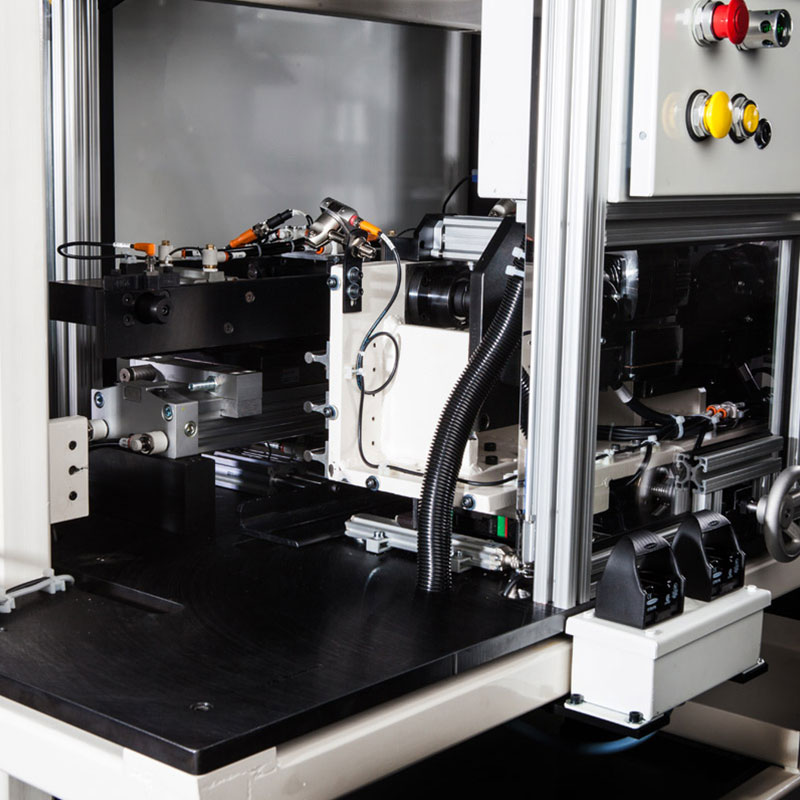

- Multiple Rams

- Rotary and Shuttle Tables

- Press Power Package Choices

- – Servo Ball Screw

- – Hydraulic

- – Pneumatic

- Controls systems and Data display

- – PLC Controlled

- – Process Monitoring

- – Signature Analysis

- – Data Output to Factory Reporting Systems

- Guide’s Standard Series

- – Multiple Standard Options

- – Reduced Lead-time

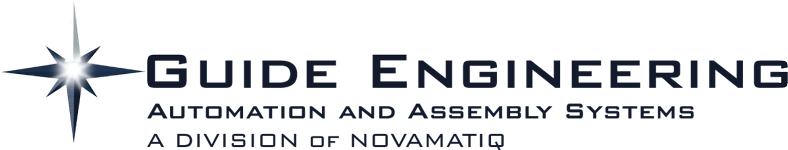

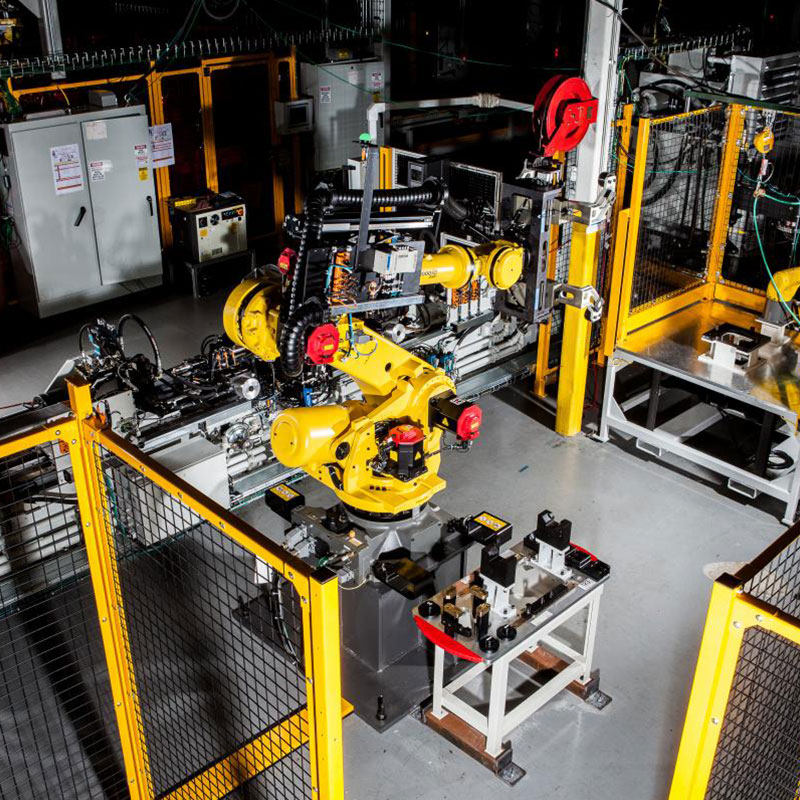

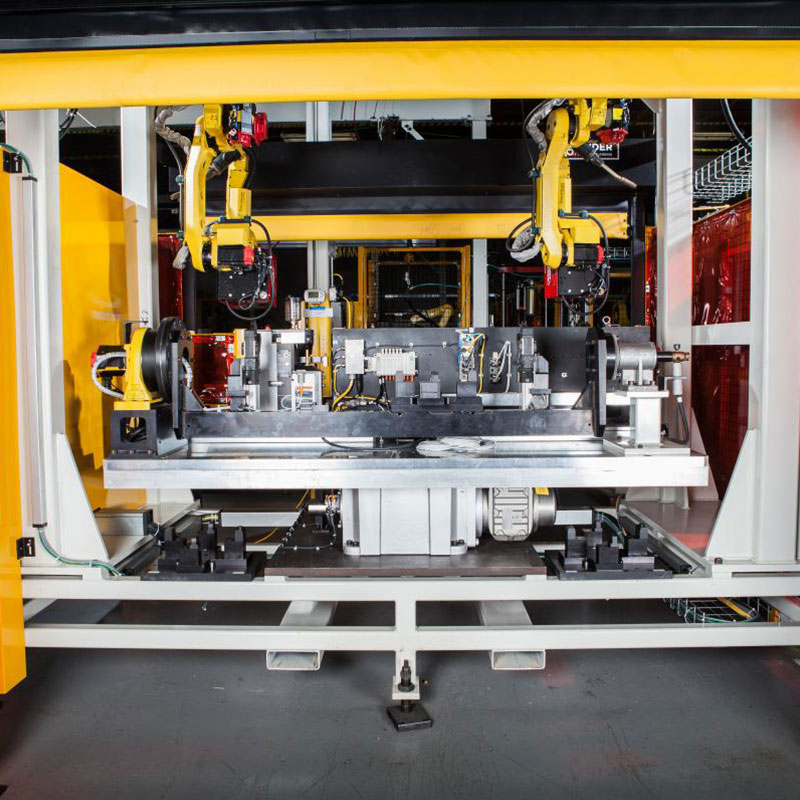

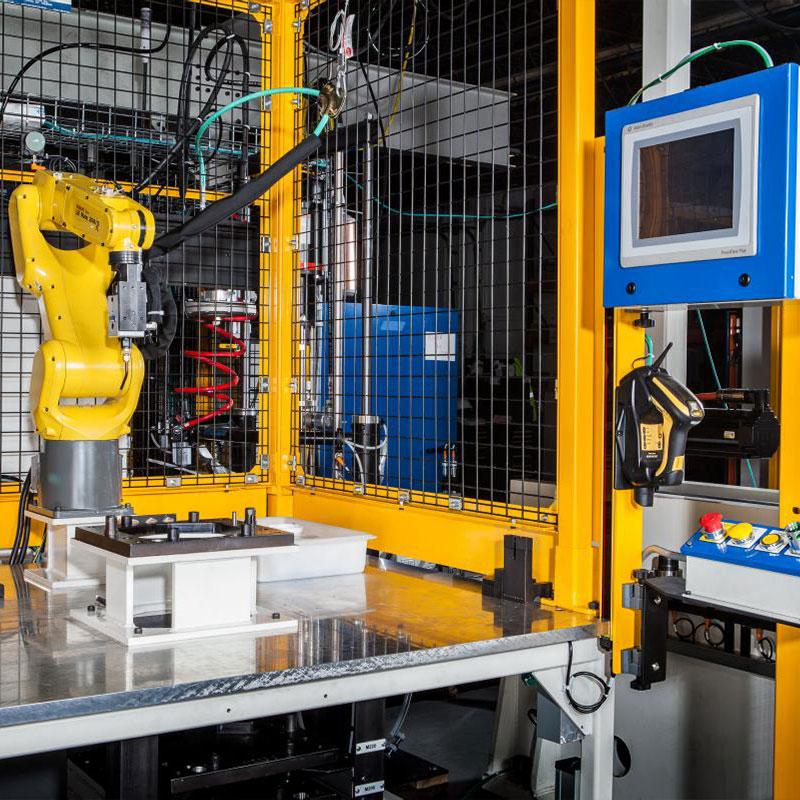

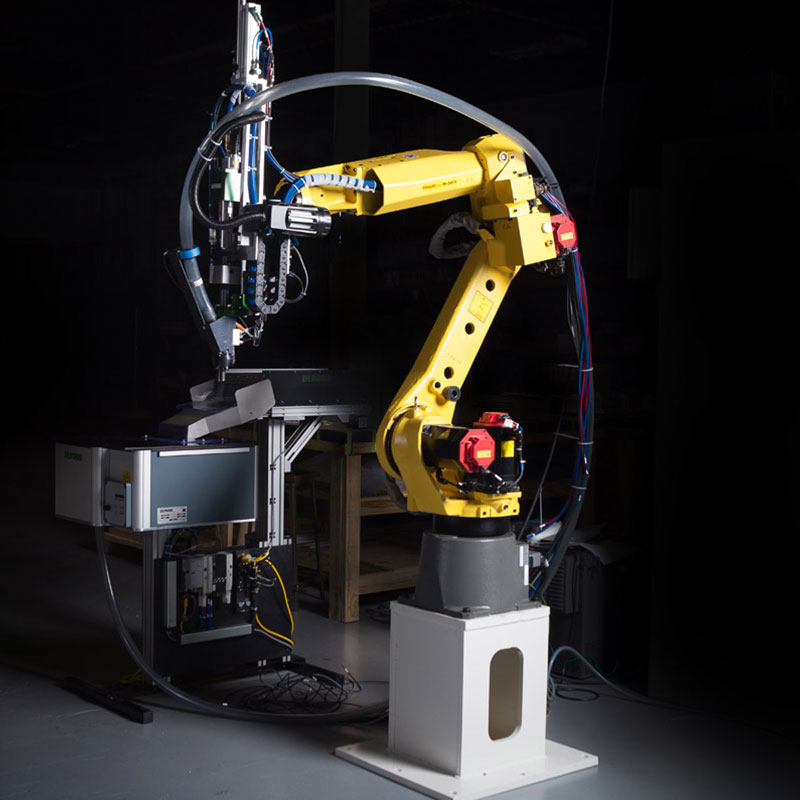

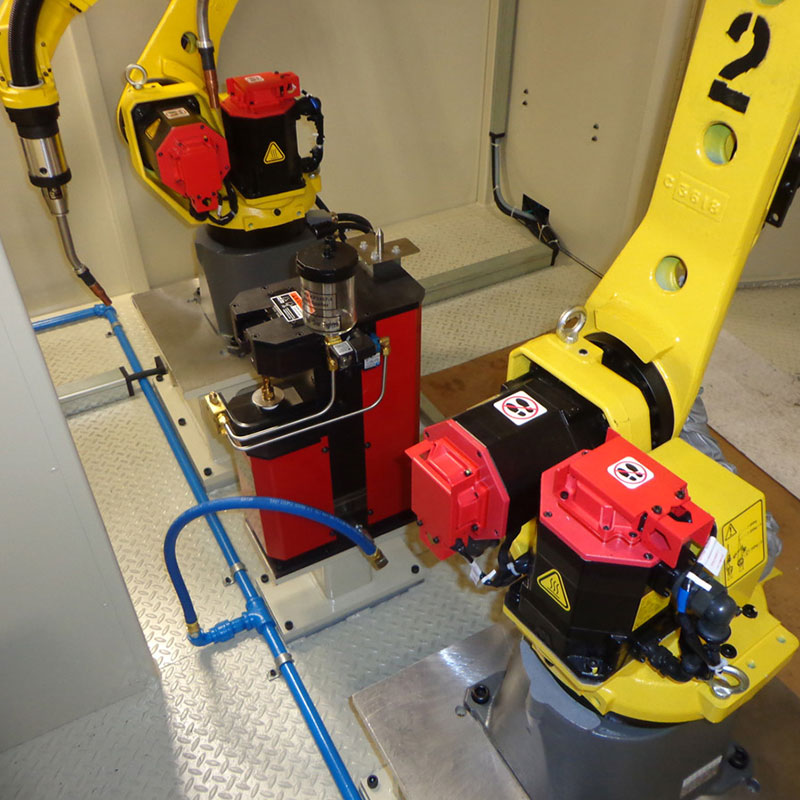

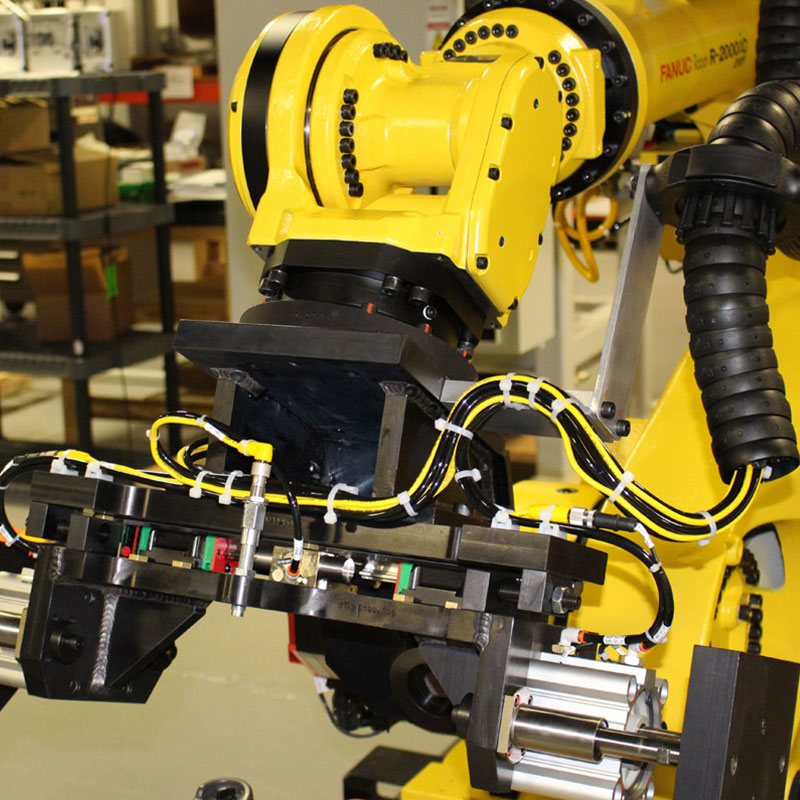

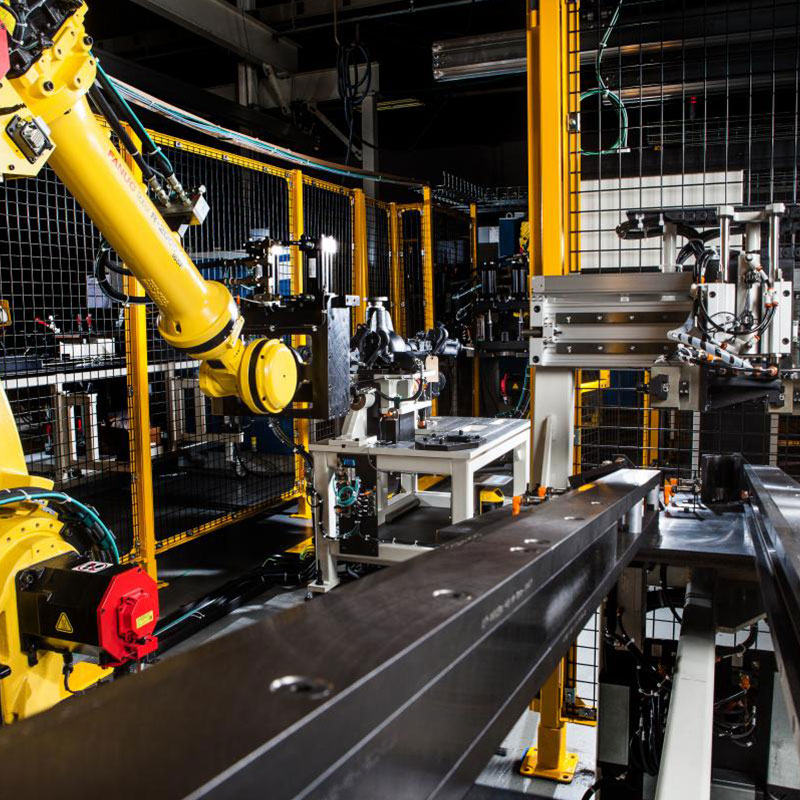

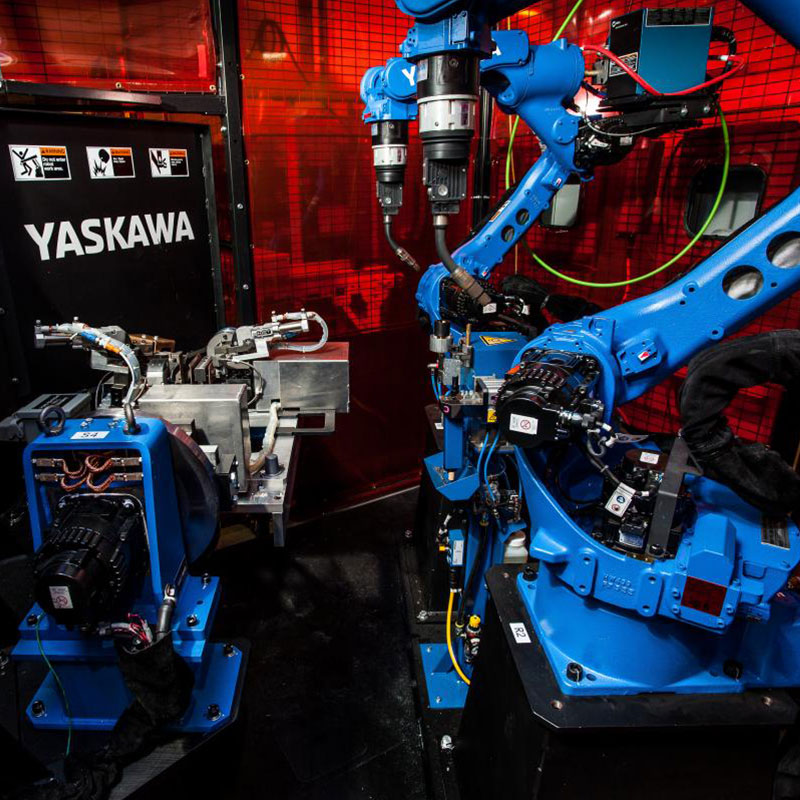

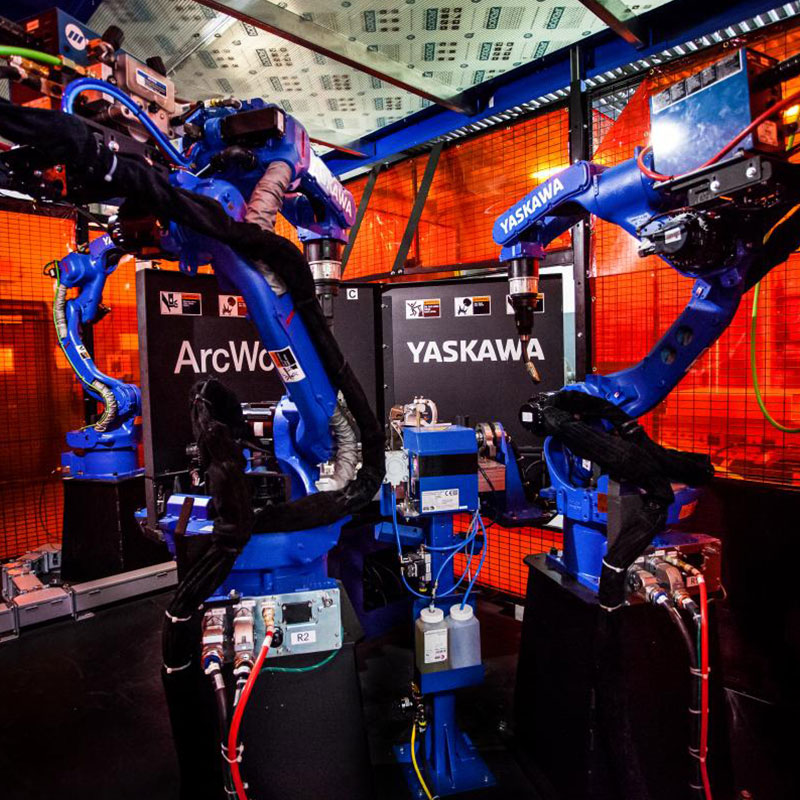

ROBOTICS

Our team of engineers, toolmakers, and electricians will provide you with reliable solutions to your automation challenges:

- Material Handling

- Welding

- Dispensing

- Vision Guidance

- End-of-Arm Tooling

Services include:

- Simulation

- Programming and Integration

- Safety System Design

- Installation and Start-up Support

TEST & MEASURE

Today, process validation is a part of manufacturing.

We understand these requirements. Guide Engineering manufactures precision measurement equipment that enables you to gauge your individual components, as well as your completed assemblies.

- Leak Testing

- Torque Testing

- Drag Torque Testing

- Bearing Pre-Load Testing

- Assembly Torque to Rotate

- Contact Measurement to 1 micron

- Roughness Testing

- Gear Lash

- Fluid and Sealant Volume Measuring